Honeycomb Fabrication

Structural & Non-structural

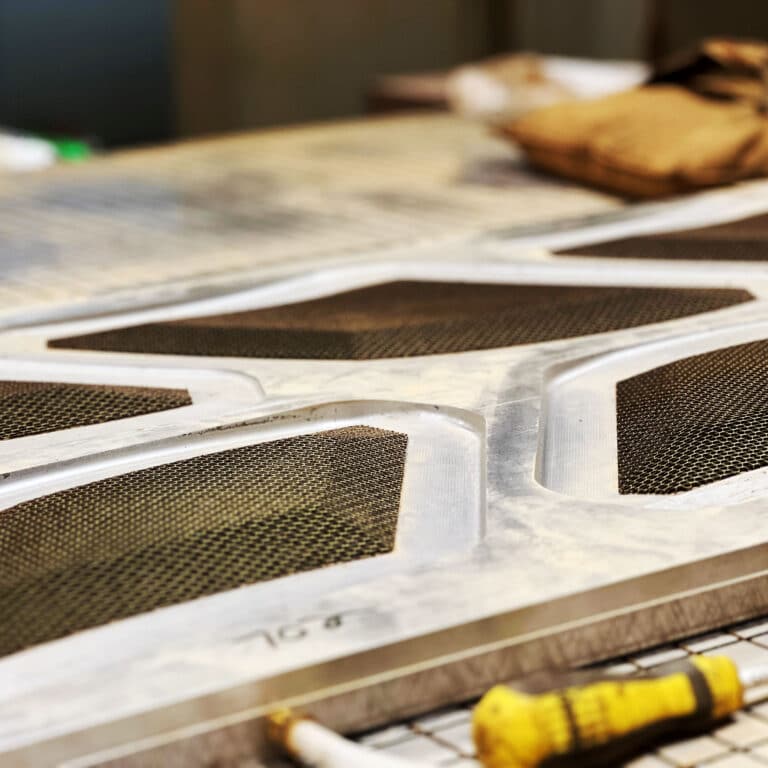

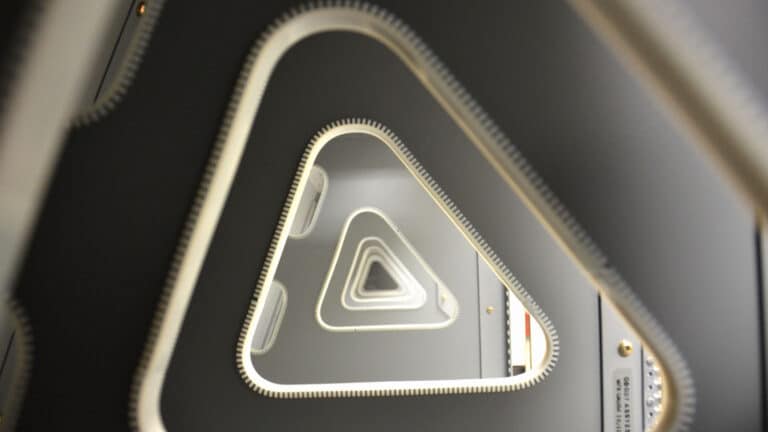

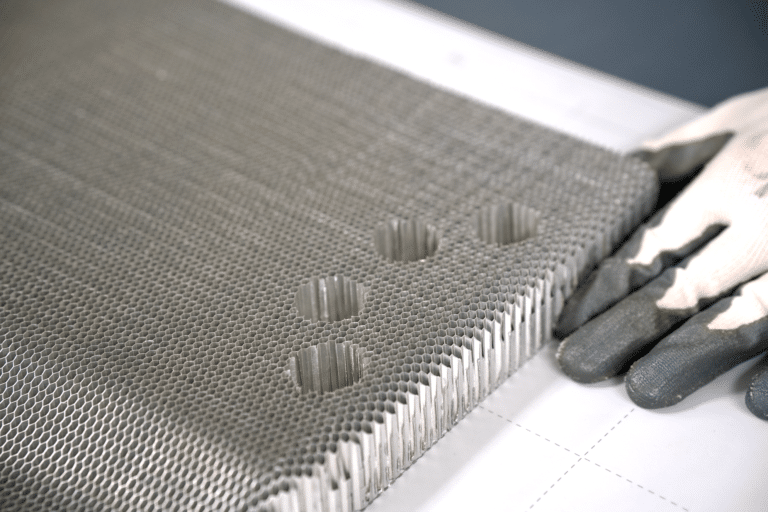

MachineTek profiles structural aluminum honeycomb of various cell sizes, foil thicknesses, and alloys. In addition to profiling expanded aluminum honeycomb, MachineTek often finds it advisable to profile aluminum in the unexpanded state, which is then followed by expansion to create the desired cross-section. Roll-forming, heat forming, potting, and edge bonding are additional processes associated with aluminum honeycomb fabrication.

MachineTek also profiles aramid fiber honeycomb, including Nomex®, Kevlar®, and fiberglass-impregnated fibrous honeycomb. Additional processes involving aramid core include bonding, heat forming, edge splicing, and potting.

Other structural and non-structural honeycomb materials such as stainless steel, Hastelloy®, inconel, carbon fiber, plastic, and other specialized materials have been successfully processed by MachineTek for a wide range of applications.

Depending upon the size, shape, complexity, material, dimensional accuracy, and other characteristics of the component, MachineTek can select from 5-axis CNC, 3-axis CNC, or manual methods and equipment to optimally produce quality honeycomb components from any of the listed materials.