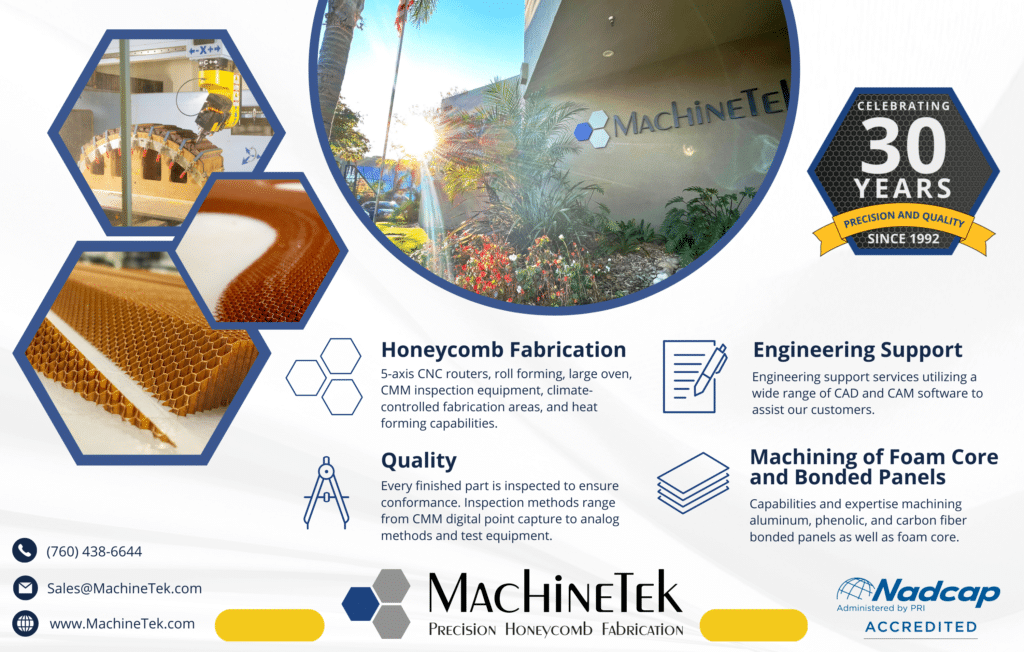

Short Lead Time and Quality are MachineTek’s Greatest Value-Added Services

In the high-stakes realm of aerospace and defense manufacturing, where precision is non-negotiable and timelines are mission-critical, MachineTek delivers what matters most to get your program on track.

With over three decades of dedicated service, we have honed our expertise in honeycomb and foam core fabrication, delivering unparalleled quality and lead times that consistently exceed industry expectations.

We understand our customers (Primes, Tier 1 & 2 suppliers), don’t just need parts, they also need customer service that is reliable and responsive.

A Legacy of Specialized Excellence

Founded in 1992 by U.S. Air Force veteran Kevin Darroch, MachineTek emerged to fulfill a specific niche in the aerospace industry: Precise fabrication of honeycomb and foam core components.

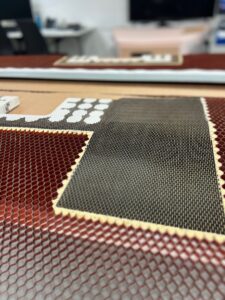

Over the years, we have expanded our capabilities to include advanced services such as heat forming, bonding, potting, and complex profiling, all while maintaining our unwavering focus on core fabrication.

Our 21,000-square-foot, climate-controlled facility in Carlsbad, California, is equipped with the equipment necessary to meet the most demanding specifications with efficiency and accuracy.

Speed Without Compromise

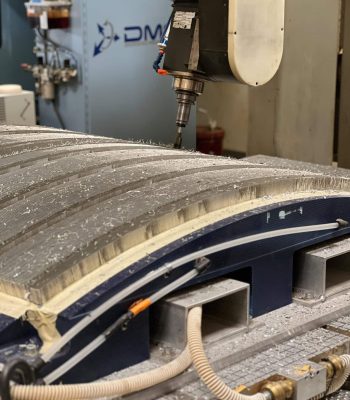

At MachineTek, we’ve engineered our processes for optimal efficiency in core detail fabrication. Our streamlined operations and experienced team allow us to move faster than traditional core fabricators.

Depending on material availability and job complexity, we can offer lead times as short as one week. This agility is particularly significant in an industry where supply chain disruptions have extended lead times by 30–50% in recent years, with core components often being quoted with 12 to 26 weeks lead times.

Whether it’s delivering one-off expedited kits or supporting multi-year production programs, we provide realistic lead times our customers can trust. Time and again, this has been critical to program success. We don’t just meet delivery dates – we enable them.

Quality That Earns Trust

Honeycomb and foam core fabrication requires more than just tooling and material. It requires technical know-how, discipline, and a culture of quality that permeates every step of the process.

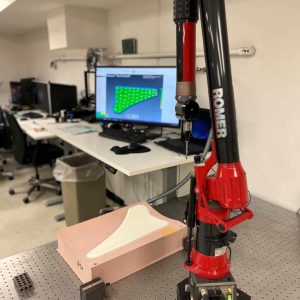

From CNC machining to forming to bonding and splicing, every part we fabricate is held to the highest aerospace standards, and validated by CMM inspection.

Strategic Partner in Precision Core Fabrication

MachineTek’s reputation has been built through long-term partnerships with aerospace leaders who value responsiveness and accountability. If your team is looking for a core detail fabricator that understands urgency, delivers repeatable quality, and makes your program priorities our own, then let’s talk.

Contact us to learn how our commitment to quality and timely delivery can add value to your operations.